Alloy is the basis for the high value application of metal materials.

Diversified high-quality metal powder is the key to the success of the alloy. The metal industry uses alloy design to enhance the application of materials.

Applying alloy powder technology to increase the material wide applications.

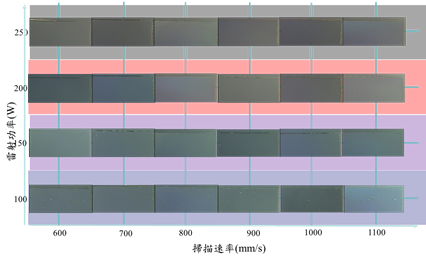

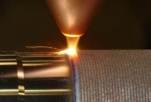

For example, by surface coating, the performance of the surface of the workpiece is increased to achieve high value.

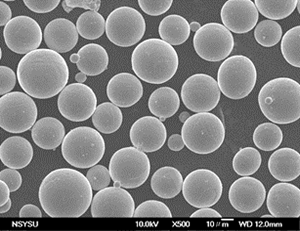

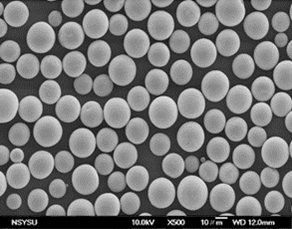

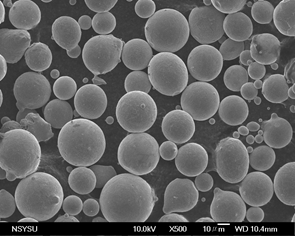

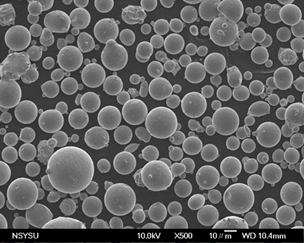

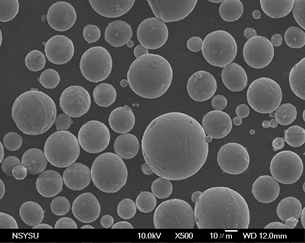

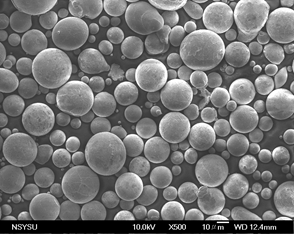

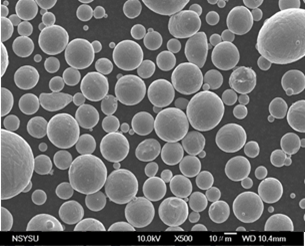

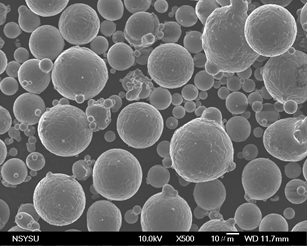

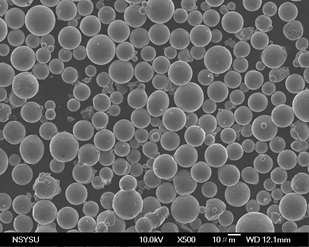

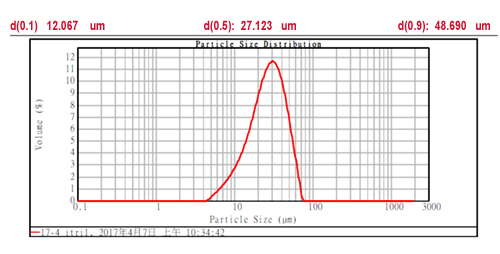

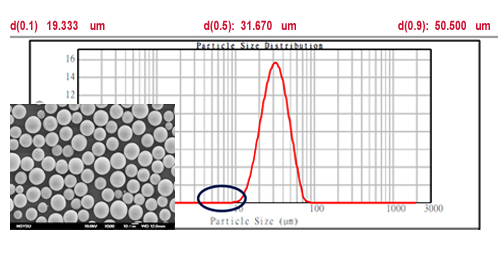

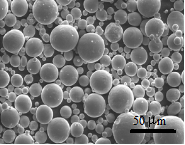

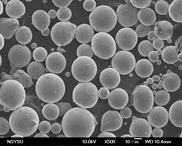

The high-valued alloy powder should have good fluidity, high spheroidization rate, uniform composition, good particle size ratio, and fine structure microstructure. It can be adjusted by inert gas coating technology and parameter control to obtain high quality alloy powder.

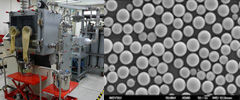

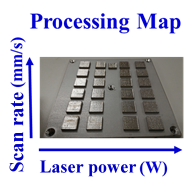

Through the design and simulation of the gas atomizer, the laboratory can obtain high fluidity, high spheroidization rate, uniform composition of high-quality powder with size between 10 and 65 microns, and the yield rate can reach more than 50%, making the product more competitive.

High-quality alloy powder can be used in 3D printing, thermal spraying, laser coating and powder metallurgy to achieve high valued components.

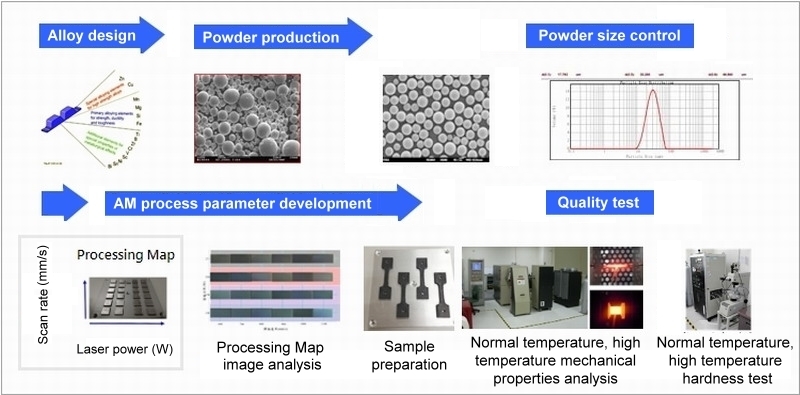

This lab provides integrated services for alloy design, powder atomization and process parameter development to meet customers' needs for small quantity wide variety customizations and to assist customers to achieve desired alloy formulation.

MCL, ITRI provides the alloy powder integration service, from basic alloy design and various melting techniques to the production of various alloy powders, particle size distribution control, process parameters, material verification, and laser coating, powder metallurgy, etc. various processes.

We provide complete solutions for different types of customers and sincerely invite you to participate in research and development to jointly creating the blue ocean business opportunities of alloys. |

Gas atomization alloy powders

Gas atomization alloy powders

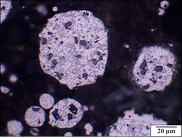

Powder sieving & particle size

Powder sieving & particle size

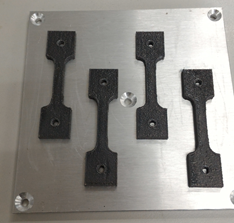

Powder metallurgy

Powder metallurgy Alloy ingot

Alloy ingot

Thermal Process

Thermal Process Thermal processing

Thermal processing

Special alloy material

Special alloy material